|

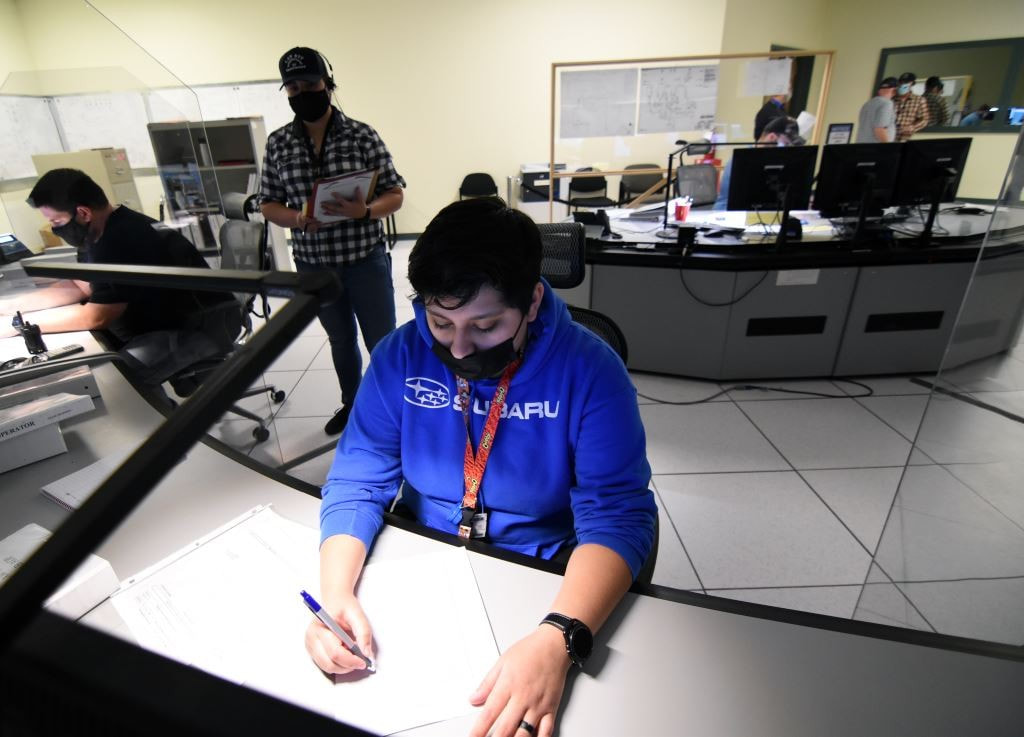

The Hanford Vit Plant team recently reached a historic milestone when its first crew of commissioning technicians became fully qualified control room operators.

"The Bravo crew set the standard, and we’ve qualified additional crews since," said Valerie McCain, project director and senior vice president for Bechtel National, Inc., the EM Office of River Protection (ORP) prime contractor designing, building and commissioning the plant. "It is an important achievement as we ensure the people, plant, and paperwork or processes are ready as we go into melter heatup and cold commissioning." The control room the operators will work in is located inside the Low-Activity Waste (LAW) Facility, where radioactive and chemical waste from the tank farms will be vitrified, or immobilized in glass, for safe disposal as part of Hanford’s Direct-Feed Low-Activity Waste (DFLAW) Program. The first-ever control room operating crew completed its final qualification evaluations in a simulator facility as Melter 1 and Melter 2 operators, process operator, utility operator, Balance of Facilities/Analytical Laboratory operator, and control room supervisor. During the evaluation, a team of instructors observed each individual performing normal operations as well as responding to abnormal and emergency conditions. "The certification of the first crew of control room operators is the culmination of extensive training," said Mat Irwin, ORP deputy assistant manager for the plant. "It’s a truly important achievement on our path to tank waste treatment." Subsequently, the remaining three crews have also been qualified. The entire Hanford Site is preparing for a shift to 24/7 operations, when vitrification of tank waste is scheduled to begin as part of the DFLAW Program. That program is a system of interdependent projects and infrastructure improvements, managed and highly integrated, that must operate together to vitrify the waste. During vitrification, waste treated at a tank farm to remove radioactive cesium and solids will be fed directly to the LAW Facility’s melters. The waste and glass-forming materials will be mixed, heated, and poured into specially designed stainless-steel containers. The containers will be transported a short distance to the site’s Integrated Disposal Facility for disposal. The plant facilities can be viewed using the self-guided Hanford Virtual Tour.

0 Comments

Leave a Reply. |

Have News?Email your press release and a photo to Austin Regimbal, Marketing & Communications Director. Press releases are posted in their entirety. This is a free benefit for members of the Tri-City Regional Chamber at the Connect level and above. Archives

July 2024

|

|

Copyright © Tri-City Regional Chamber of Commerce. All rights reserved.

7130 W Grandridge Blvd., Suite C, Kennewick, WA 99336 USA Phone: (509) 736-0510 [email protected] |

Hours

Monday - Thursday: 8 am - 5 pm (closed for lunch 12 - 1 pm) Friday: 8 am - 12 pm Closed Weekends |

RSS Feed

RSS Feed